EEE Component Engineering and Procurement

- Spur Electron provides EEE component Engineering and Procurement service capability

- The EEE component Engineering and Procurement teams are closely integrated with our PCB assembly service

- This provides a seamless service from initial component list review through to delivery of a fully qualified PCB assembly

- Engineering and Procurement have been a cornerstone of Spur’s service offering for over 35 years

- Spur Electron Engineers mitigate design risk by identifying areas of major concern during the Declared Components Lists (DCL)

- EEE components used for high reliability, harsh and non-maintenance applications in Aerospace and Space need to be carefully selected

- Commercial aspects relating to obsolesce, availability, delivery, cost, are also key elements to be considered

- Mission and environmental requirements need to be assessed and applied with respect to qualification, radiation tolerance and technical compliance

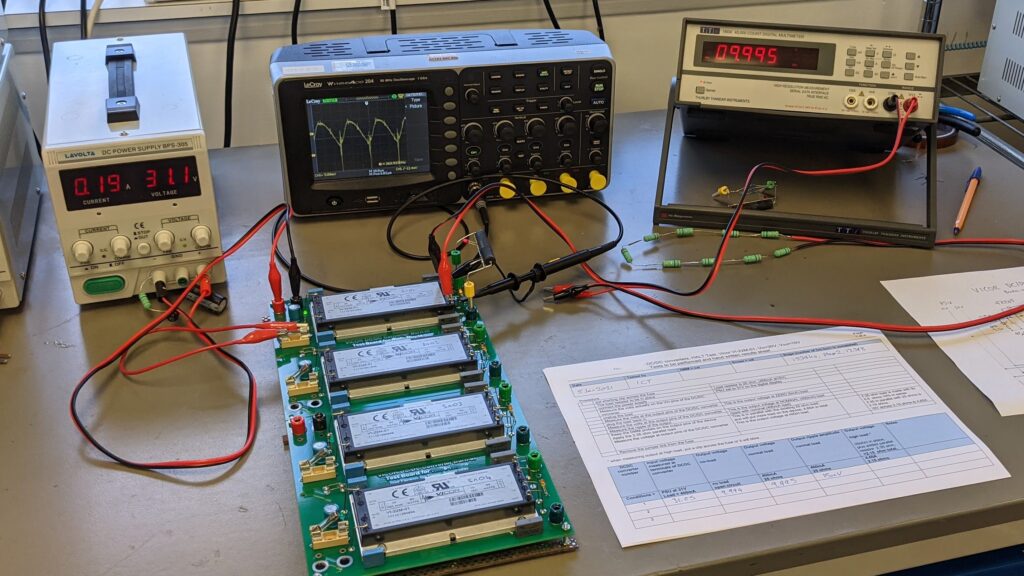

- Specific tests including screening, Lot Verification Testing (LVT) and Radiation Verification Testing (RVT)

- Obsolescence monitoring and planning for Last Time Buy (LTB), Process Change Notification (PCN) and/or recommending alternative components

- Parts Approval Document (PAD) preparation and management of the Parts Control Board (PCB) process

- COTS components from COTS through to COTS Plus Analytical Testing, COTS Plus Screening

- ESA Class 1 Components (e.g. JANS, QML V, Class K), ESA Class 2 Components (e.g. JANTXV, QML Q, Class H), and ESA Class 3

The Spur Electron component Engineering team provides a unique service capability within the international Space and defence sectors. The use of high reliability components is required for long term, harsh or non-maintainable environments and they must be carefully selected to meet the stringent mission requirements for quality, reliability, radiation and heritage. New and evolving technologies offer capabilities vastly superior to those of only a few years ago, but are very often untried under harsh operational or environmental conditions. Where qualified and proven options are not available, Spur Electron will offer advice and guidance, which may include:

- Selection of a replacement device with known reliability history.

- Constructional Analysis (CA), to assess the robustness of a component to meet specific long term operational needs.

- Specific tests, such as Lot Verification Testing (LVT) or Radiation Verification Testing (RVT), where no information is currently available.

- Specific Quality Conformance Inspections (QCI) or independent inspections (Pre-Cap/Buy-Off) in a Procurement specification to assure the quality and reliability of the delivered item.

- Identification that a component type is becoming Obsolete, is subject to a Last Time Buy (LTB) or has a Process Change Notification (PCN) and recommending replacements where possible.

The use of these parts will usually require a Parts Approval Document (PAD) and Spur will manage this process from preparation to the Parts Control Board (PCB) with the ultimate end user. Spur Electron’s Engineers are closely supported by its Laboratory staff and have carried out many in-depth studies concerning current component material problems. Almost all of these have resulted in potential solutions or preventative measures that can significantly affect electronic design at every level. Members of component Engineering are also integrated into the component Procurement team, ensuring that customers maintain Engineering support throughout the Procurement cycle. Get in touch!